Hvala za snemalni pozdrav!

Najprej naj vas opozorim; ko se spravim pisat pišem na dolgo in mnogokrat raztreseno, saj imam problem, kako čimveč informacij podat v nekaj vrsticah, na koncu pa izpade ta šmorn

.

Če koga to moti naj pove, bom nehal

.

No,... kul da se je soulfood spomnil na te BBCijeve raziskave, na njihovi strani jih je kar nekaj pod "archive". Skoraj bi pozabil.

Z njimi sem se spoznal, ko sem delal za BBC (skoraj 6let) in smo malo ob pivu in ginu (beton) debatirali o akustiki. Takrat me je prvič zamikal modularni dizajn, saj je mnogo radijskih studijev na BBCju narejeno po tem principu.

http://www.bbc.co.uk...ive/index.shtml

Tako da sem s temi fanti še vedno na vezi in takrat sem si prvič lahko pobliže v njihovi knjižnici ogledal te sheme in principe tudi na papirju.

V bistvu dober (beri odličen) broadband absorber dandanes z odličnimi novimi materiali ni tako težko naredit (sicer gre dosti časa in $$$), ampak če se hočeš egzaktno prepričati v njihovo dejansko delovanje je potrebno najemati testne anehoične sobe (ena super je na Dunaju-cena na testiranje cca. 2000 EUR), kjer pa je tudi catch; meritve pod 100 Hz niso nujno prave, ampak so rezultati meritev bolj informativne narave, saj gigantskih sob za zvočna valovanja pod 120Hz praktično ni (saj si predstavljate kakšen ogromen val je recimo 50 Hz).Zato si pomagajo s Kundtovimi tubami, kjer dajejo v cev eksampl in s preciznimi mikrofoni merijo zvok katerega oddaja posebni zvočni vir (glej Bruel&Kjaer).

Tukaj pa so še drugi problemi glede meritev,...

in zmeraj se najde nekdo ki je dal delat meritve v IBM testno sobo, ta drug proizvajalec panelov pa v tisto in ono sobo. Rezultati se pa razlikujejo, čeprav so dizajni absorberjev lahko identični. Mnogokrat se primerjajo s konkurenco (celo konkurentne izdelke s svojimi vred dajo merit in si mečejo kolena pod polena

)

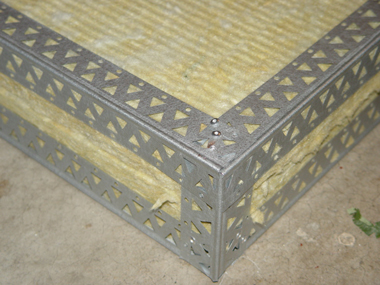

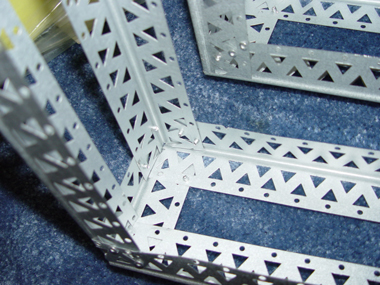

Da pa ne bi kdo mislil da so Ethan Winerjevi "realtrapsi"kaj specialnega, to je zgolj sendvič konstrukcija 2 "steklenih" plošč (morda ima zdaj kameno volno, ne vem) vmes pa je FRK- to je tista alu folija nalimana na tervol (določeni produkti jo imajo). Ta folija deluje na enakem principu kakor pistonična membrana od prej omenjenega dr. Fuchsa.Za ceno pa ne vprašajte, po 200 eurov in več, pa še poštnina...

To moraš bit malo nor da kupiš, deluje pa do nekje menda 70-80Hz.

Pa še ena finta: tisti ki vas to zanima in ste si malo prečitali o membranskih absorberjih, ste najbrž opazili kontradiktornost.

Namreč Ethan W. in kup drugih akustičnih inženirjev so dolgo (nekateri še zdaj) zagovarjali, da mora membrana prosto vibrirat, torej mora imeti 1 ali 2 cm prostora, takoj za tem airgapom pa izolacijo (kakšno pač), drugače kao ni v redu in ne deluje.

No, potem pa si poglejte kako so sestavljeni realtrapsi (glih Ethan W.) ali RPGjevi prej omenjeni absorberji.Mnogokje (AVS forum in drugi znani) se takšni in drugačni stručkoti (eni imajo celo prave diplome iz akustike

)še zdaj prepirajo kaj je prav in kaj ne.

Tisti ki se pretirano ne pretvarjajo je recimo GIK acoustics, fant ki dela panele iz menda kamene volne 100kg/m3. Sicer so broadbandi debeli tudi skoraj 20cm (18cm), kar pa ni najbolj praktično, saj ti kaj kmalu sfali pol metra sobe ali celo skoraj meter (absorberji na vsaki strani in še priporočljiv airgap-cca 10,20cm do stene).Nima membran, samo izolacija (cene so tudi OK).Meritve pa tako kažejo do 5000 morda 8000Hz, saj nad tem območjem visoke frekvence odbija takšen gost materijal...kar pa bi se dalo rešit z gostejšo (a vseeno transparentno) tkanino ali morda dodatnimi ala piramidicami

.

Poglejte si GIK tri trap, to je iz foruma-http://forum.studiotips.com/viewforum.php?f=1 -studiotips superchunk totalna kopija.

In ja, ta stvar res deluje,malo prebrskajte po tej strani, kjer so po mojem mnenju najbolj praktične in poceni rešitve, ne pa akustični konzultanti, ki te oderejo iz kože (beri $$$), rezultati teh home made produktov pa mnogokrat presegajo komercialne. Te superchunkse pa lahko narediš takorekoč iz odpadne izolacije.

MinimalB:

S svojim zahtevnim tretmanom sobe si verjetno eliminiral frekvence pod 120Hz (upam da si kaj računal če si se že tako namatral

).

Tako da se sedaj moraš ubadati samo še s frekvencami nad 120, tervol DP8 ali DP6 - toge plošče bi bile dobra solucija, pa še poceni.

Helmholtza se izogibaj, če ne maraš preveč matematike-in drugače prevelike koloracije zvočne slike.Zanimivost: nekatere cerkve iz srednjega veka imajo Helmholtzove resonatorje ("opeke" so votle) in imajo majhne odprtine (ne vem na koliko so "tjunane"). Zvok pa je baje fantastičen. Sicer pa ko si si naredil perforacijo, če ne bi dal od zadaj izolacije bi imel en velik Helmholtzov resonator, sadaj pa služi bolj kot difuzor. No pri "malih luknjicah" se pripisuje še en fenomen tukaj si lahko preberete:

Advances in Perforated Panels - Part 2: Microperforated Panels

by Dr. Keiji Oguchi

In this article, I will introduce our readers to the scientific basis, and practical applications of microperforated panels (MPP). MPP come in foils, sheets and panels, and are characterized by having a 0.5 - 2.0% ratio of perforations to solid area and sub-millimeter, cylindrical perforations manufactured with uniform patterns and tolerances.

<< Characteristics of MPP >>

MPP hole & Match head

When a MPP, sheet or foil is placed in front of a rigid, sound-reflecting surface (such as a wall), with a layer of air between the surface and the MPP, the air mass inside the microperforations and the air spring caused by the layer (or cavity) of enclosed air together form a Helmholz resonator. (A simple example of a Helmholz resonator is the resonance heard when a person blows across the top of a soda-pop bottle, making the air trapped in the bottle into an air spring.) Helmholz resonators generate resonance at specific frequency ranges. The resonant frequencies of MPP currently available are mid-range frequencies of 250 Hz - 1kHz.

A key difference between the perforated panels I discussed in my May 2005 article, "The Science, Uses and Advances in Perforated Panels -- Part 1" and MPP is the tiny size of the holes, which measure less than 1 mm in diameter. Because of the holes' extremely small size, when the air within the hole vibrates and converts from sound to heat energy, marked sound absorption occurs for frequencies in the resonance vicinity, eliminating the need for backings of porous sound-absorbing materials such as glass wool, provided the sound frequencies needing to be absorbed are within the 250 Hz - 1kHz range. A practical application of the phenomenon is that a sheet or panel of MPP can be set in front and slightly apart from a wall and the configuration will absorb mid-range frequencies. Furthermore, if transparent MPP are used, the resulting configuration is a visually transparent sound-absorbing solution.

<< The Seminal Work of Prof. Maa >>

Transparency of MPP foil

The suggestion to use microperforations comes from Prof. Dah-You Maa, Research Professor at the Institute of Acoustics, Academia Sinica in 1975. I first learned about microperforations in 1992, at the 14th International Congress on Acoustics in Beijing. The conference presentation I attended lasted less than 20 minutes, and did not enable me to fully grasp all of the details and ramifications of Prof. Maa's work, but the salient point I gleaned from that presentation was the feasibility of a transparent sound absorbing material.

In the years following the Beijing International Congress on Acoustics presentation, research into the applications of sound absorbing structures continued, especially in China and Germany, and the research produced numerous papers. Among the research is a paper in which the relatively easy analogy of an equivalent electrical circuit is used to discuss the sound-absorbing structure of microperforations. In the analogy using an equivalent circuit, the method considers a circuit that exchanges a mechanical element for an electrical element. When substituting the equivalent circuit for the absorption that occurs with microperforations, the electrical coil represents the air mass in the holes, the electrical condenser represents the air spring (of the air layer between the MPP and the rigid surface), and the conversion of vibration energy to heat is represented by electrical resistance, building the equivalent circuit of the analogy.

<< Practical Applications of MPP >>

Currently, use of MPP in Japan is dependent on supplies of MPP from Europe and the United States, because there is no local Japanese manufacturer of the material at the moment. European and U.S. suppliers manufacture MPP from metals, polycarbonates, Teflon, acrylics and flame-retardant plastics. By using transparent or translucent MPP, it becomes possible to achieve some level of sound absorption performance even in spaces that are primarily enclosed by glass surfaces.

As I mentioned earlier in this article, MPP exhibit a selective sound absorption characteristic concentrated on absorption of mid-range frequencies. By using multiple layers of MPP with different hole diameters and different distances between the holes, the effective sound absorption range can be expanded to a wider range of frequencies. (This technique is documented in L. Cremer et al: "Principles and Applications of Room Acoustics.") In addition, research by Asst. Prof Sakagami of Kobe University demonstrates that if two sheets or panels of MPP are placed with an air cavity between them, sound absorption of lower frequencies can be obtained. (One possible room acoustics application might be to suspend the two layers from an overhead structure.) These creative suggestions for expanding the usefulness of MPP, make me increasingly hopeful that this technology will continue to lead to many useful research breakthroughs and the development of useful products.

One example of a supplier of MPP products can be found at:

http://www.kaefer.co...microsorber.htm

Difuzorji so poleg absorberjev še bolj interesantni, virtualno povečajo sobo, saj zvok čimbolj enakomerno razpršijo po prostoru (vsaj se trudijo),tukaj je spet potrebna matematika, saj broadband difuzerjev skoraj ni, če pa so, so ogromni in posledično dragi. O tem drugič.

Ampak normalno velike difuzorje je moč naredit za malo denarja, vsaj če poznaš svoj prostor. Ni vedno potrebno izdelovat "phase grating" ali "quadratic residue" difuzorje (RPG), ampak lahko uporabiš policilindre iz vezanega lesa, vendar se moraš malo pozabavat s sweet-pointom v snemalni sobi, saj cilindrični manj enakomerno razpršijo zvok.Cenovno in prostorsko niso tako požrešni.Tube trapsi uporabljajo to metodologijo, eno linijo produktov imajo celo elektronsko uravnavane.

Soulfood: za akustiko sem vedno ZA!

Vem, vem, dolg sem.

V resnici sem tudi malo večji

.

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj

Povečaj